metal roofing 26 gauge factory

Além disso, as coberturas tipo shed também são projetadas para uma melhor ventilação. Os telhados inclinados permitem uma circulação de ar mais eficiente, ajudando a regular a temperatura interna da fábrica. Isso é especialmente importante em processos industriais que geram calor ou em ambientes que exigem controle específico de temperatura e umidade. Uma boa ventilação não só melhora as condições de trabalho, mas também pode prolongar a vida útil dos equipamentos e produtos armazenados.

sheet shed roof factory

Typically, galvanized iron sheets are available in various thicknesses measured in gauges. The most common standards range from 18 gauge (approximately 1.2 mm) to 26 gauge (approximately 0.5 mm). Thicker sheets, like 18 or 20 gauge, are commonly used in applications requiring structural strength, such as construction and industrial settings. In contrast, thinner sheets are often applied in manufacturing and household fixtures where weight and flexibility are crucial.

2. Cost-Effectiveness Galvanized corrugated iron is often more affordable than other roofing materials such as tiles or premium metals. When selecting a supplier, you’ll want to ensure they offer competitive pricing without sacrificing quality. This makes it an excellent choice for budget-conscious projects.

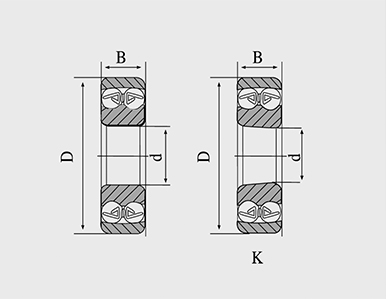

nu 316 bearing. Typically made from high-quality steel, these bearings are often heat treated for increased hardness and resistance to wear and tear. Some manufacturers also incorporate anti-corrosion treatments, enhancing their performance in harsh environments.

nu 316 bearing. Typically made from high-quality steel, these bearings are often heat treated for increased hardness and resistance to wear and tear. Some manufacturers also incorporate anti-corrosion treatments, enhancing their performance in harsh environments.